KFCOMS will be a company that grows with its customers through innovative materials and future-oriented changes.

Raw Material

Glass Fiber

Fibers derived from raw materials such as limestone, silica and borax are among the most common composite materials. They boast excellent tensile strength, superior heat resistance, chemical durability, electrical insulation and wear resistance.

| Type | E-GLASS | C-GLASS | ECR-GLASS |

|---|---|---|---|

| Specific gravity | 2.54 | 2.50 | 2.71 |

| Tensile strength (MPa) | 3,400 | 3,000 | 3,300 |

| Elastic modulus (GPa) | 72 | 69 | 72 |

| Elongation at break (%) | 4.8 | 4.8 | 4.8 |

| Coefficient of thermal expansion (10-6) | 5.0 | 7.2 | 5.9 |

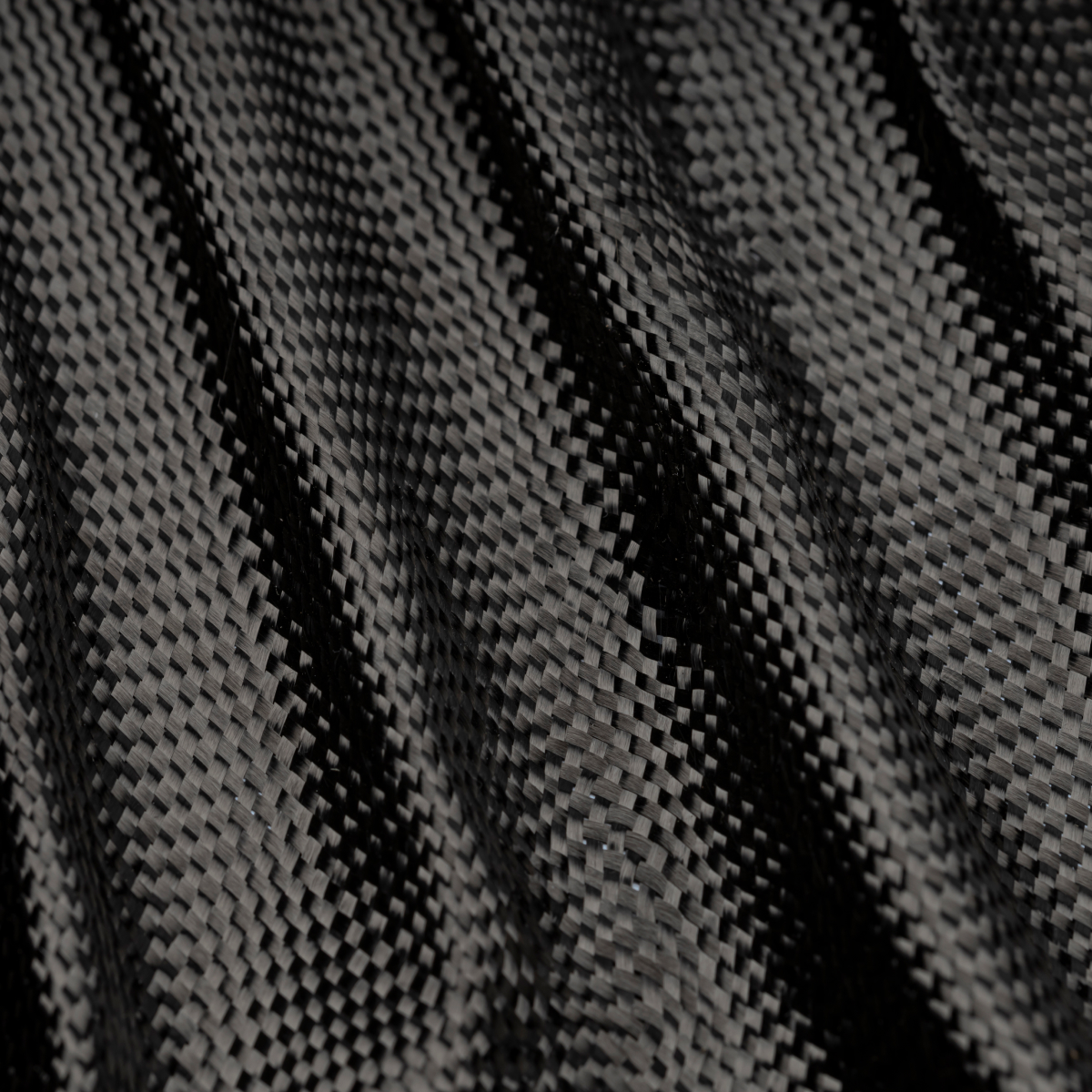

Carbon Fiber

Carbon Fiber is a material composed of carbon with a graphite crystal structure. It is lighter than aluminum and has stronger elasticity and strength compared to iron. As a result, it is commonly used as an advanced composite material that can replace metals in aerospace, high-performance sports equipment and other areas.

| Type | T700 | T800 | T1000 |

|---|---|---|---|

| Specific gravity | 1.80 | 1.81 | 1.79 |

| Tensile strength (MPa) | 4,900 | 5,500 | 6,600 |

| Elastic modulus (GPa) | 230 | 294 | 675 |

| Elongation at break (%) | 2.1 | 1.9 | 2.0 |

Aramid Fiber

It is a type of fiber based on polyamide. It possesses excellent strength (5-7 times that of steel) and heat resistance. Aramid fibers are widely used in various applications such as heat-resistant materials, safety suits, flame-resistant / bulletproof suits, lightweight composites and structural reinforcements in construction due to their unique properties.

| Type | Kevlar 29 | Kevlar 49 | Kevlar 149 |

|---|---|---|---|

| Specific gravity | 1.44 | 1.45 | 1.47 |

| Tensile strength (MPa) | 3,600 | 3,800 | 3,400 |

| Elastic modulus (GPa) | 65 | 130 | 186 |

| Elongation at break (%) | 4.0 | 2.8 | 2.0 |

Basalt Fiber

Fibers based on basalt with tensile strength and elasticity modulus 15-20% higher than glass fibers, exhibit excellent chemical resistance and a wide operating temperature range, making them a more environmentally friendly option.

| Specific gravity | Tensile strength (MPa) | Elastic modulus (GPa) | Elongation at break (%) |

|---|---|---|---|

| 2.67 | 4,000 ~ 4,300 | 84 ~ 87 | 3.50 |